Carbon spokes are nothing new. First introduced by German manufacturer Lightweight in 1994 with the first fully carbon wheel, carbon spokes claimed their first Tour de France win in 1997. From then until fairly recent times, they remained the reserve of niche carbon exotica.

Fast forward to today, and most major and premium road bike wheel manufacturers offer wheelsets with composite spokes. Even the traditionally conservative DT Swiss has now dipped its toe in the carbon-spoke world with its 1,174g ARC 1100 Spline 38 CS wheelset.

For lightweight wheelsets where every gram counts, the weight-to-stiffness properties of carbon spokes offer clear benefits, where they can shave more than 100g off a wheelset compared to conventional steel spokes.

But their fragility from side impacts, patent-protected production processes and minor aerodynamic deficiencies mean they’re likely to remain a premium alternative to steel, rather than a wholesale replacement – at least for now.

What are carbon spokes?

As their name suggests, carbon fibre spokes replace the standard steel spokes, but there are two different approaches – unbonded and bonded.

The former is similar to a standard wheel, with carbon spokes laced to the hub and rim like steel spokes.

The majority of unbonded carbon spokes feature a carbon shaft that is bonded to a steel or titanium head and threaded tip. This means that the carbon part isn’t actually in contact with the hub or rim body, so only minor alterations have to be made to the hub and rim to use them.

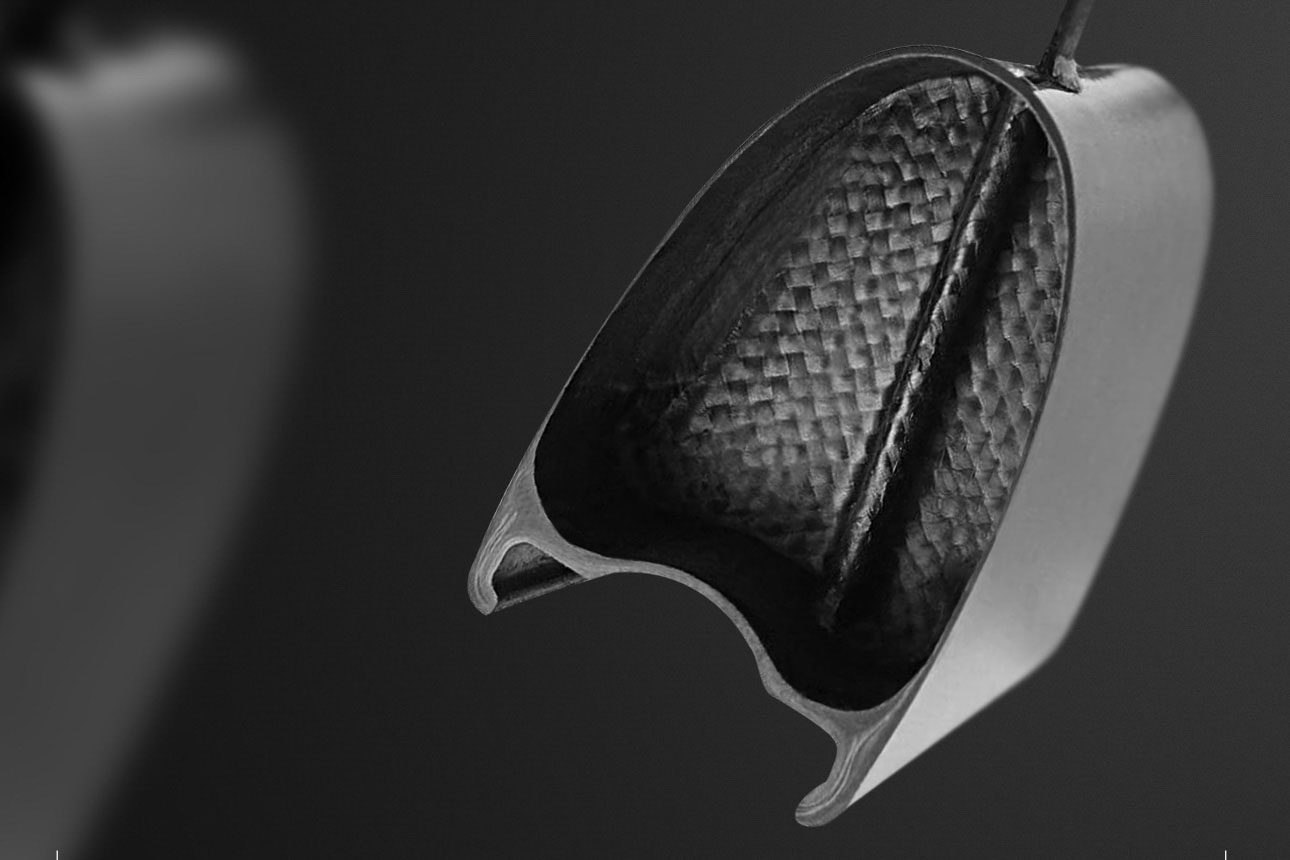

The latter is a one-piece design. Depending on the wheel construction, the rim, hubs and spokes can be separate components bonded together during the manufacturing process, or, as is the case with Syncros’ Capital SL-series wheels, all three components may be moulded as a single piece.

- Read more: New Syncros Capital SL carbon wheelset features one-piece rim, spoke and hub shell design

A significant saving

Wheel manufacturers have adopted carbon fibre spokes primarily because of the weight savings on offer.

“They’re about half the weight of a steel spoke,” says Joel Smith, managing director of Reserve Wheels, explaining that the Vonoa carbon fibre spokes used by Reserve weigh 2.5g compared to Sapim CX-Ray’s 4.75g.

When laced to a 24-spoke rim, this enables Reserve to shave 108g per wheelset without sacrificing any of the rim or hubs’ properties. “We now have a lighter, deeper section wheel, without having to reduce the strength of our rims.”

But the performance benefits don’t end there. “With the same cross section of the spoke, you can build lighter wheels, or with the same weight, you can build much stiffer wheels,” explains Michael Hübner, Lightweight’s head of R&D.

Scope Cycling’s co-founder Nieck Busser adds that you can feel the difference a carbon fibre spoke design makes from a lateral stiffness and ride quality perspective.

“The pivotal moment [for Reserve] has been this year, where Wout [van Aert] basically raced carbon spoke wheels the entire Tour de France,” says Smith.

“He kept saying they just felt way more planted with less movement in hard cornering situations where you’re going into an apex corner, hard on the brakes, and he noticed the snappiness of the wheel out of the corners as well on the rear.”

Easily damaged downsides

However, carbon spokes aren’t without their drawbacks.

From a performance perspective, the current crop of unbonded carbon fibre spokes isn’t as aerodynamically optimised as their steel counterparts. This means there is a marginal increase in drag to pay for the savings on the scales.

“If you want to build just aero wheels, you could have an advantage with a steel spoke because you can build it very thin, which is not possible… with a carbon spoke,” says Hübner.

While it’s possible to create carbon fibre spokes to the same profile and they would have enough lateral strength, he explains.

But the main downsides arise from the practical application of carbon fibre spokes during the cut-and-thrust nature of riding and racing.

“From a pull perspective, it’s a very strong product, and we hardly see any failure,” says Busser. “The difficulty is from a side impact – it’s a pretty sensitive product. Compared to steel spokes, it’s a huge difference.”

For unbonded carbon fibre spokes, this could mean a broken spoke, whereas for bonded models, like those made by Lightweight and Syncros, it could mean a whole new wheel.

“Performance-wise, I would definitely go for the carbon spoke, but take into consideration the complete picture,” says Busser.

“If you’re an amateur racer and you want to race with it, and you are in the bunch, or you do a Spring Classics or a criterium, and you hit a pedal or a derailleur with your spoke, a steel spoke can survive that; [with] a carbon spoke, it’s going to be more difficult.”

Why now?

For a technology that has been around for more than three decades, why is it only now that we’re seeing a swathe of brands coming to market with a carbon fibre spoke wheelset?

The answer lies in the improved consistency in the unbonded carbon fibre spokes themselves, and the lower barriers to entry offered by this approach.

“For the past five years that we’ve been looking into it, there was super inconsistency in the actual spokes until we found the company that everybody is using these days – Vonoa – and we started seeing consistency in spoke pull tests,” says Smith.

This has given manufacturers confidence to start investing R&D time in producing an unbonded carbon fibre spoke wheel without having to rethink the hub and rim design as with a bonded approach.

“We’ve kind of reached the design limitation [of the rim]. If you look at a cross-section, they’re so thin, so there wasn’t really a way for us to get a lighter wheelset without reducing strength. We didn’t want to do that. So [carbon spokes] was an opportunity to [reduce weight],” adds Smith.

There’s consumer demand too, with Busser saying that high-end, performance-focused customers expect carbon fibre spokes – as found on Scope’s Artech series – as standard, while Smith says that Reserve expects the technology to make up 10 to 15 per cent of its aftermarket wheel sales next year.

Bonded vs unbonded

The current trend is being driven by unbonded carbon fibre spokes, but there are pros and cons to each approach.

The unbonded path is a cheaper (albeit still more expensive than steel) approach for brands to invest in.

“We did the [bonded] front and rear for Wout [van Aert] at the Olympics last year, but that’s a long path for us. Those wheels have to be $5,500 to make them, especially consistently. I don’t know if we’re ready to go into those price points now,” says Smith.

But it also comes down to the end-user and how the product is going to be used.

“We don’t see the benefit of making it a one-piece design for durability and maintenance reasons,” says Busser. “We see a huge benefit of being able to replace the product.

“If you have a €4,000 product, and something happens to your rim or your hub, and you’re not under warranty, we can still repair products for a reasonable amount. Whereas for [bonded] wheels like Syncros or Lightweight, if it’s not over the warranty, you literally have to throw out your wheels.”

Of course, cottage artisans, such as Lightwheels Repair Service, offer repairs to one-piece carbon wheels, though whether OEMs would advocate this is unclear.

Regardless, for Syncros and Lightweight, the additional performance benefits of a bonded design are worth the risks and even greater costs.

“We are always looking for the best performance, best quality, and also the best durability,” says Hübner. “It makes sense to bond it because for a fibre composite, you are always looking for a direct connection between the fibres, and if you bond the spokes directly or laminate it inside the rim, you can use the full properties of the material.

“If you use an unbonded one with nipples and a thread, then you will lose some of the properties.”

Hubner also claims that if you bond the spokes or laminate inside the wheel, the performance remans the same for the life of the wheel. “With an unbonded spoke, it loses some of the properties over the years.”

Nicolas Rondeau, head of Syncros’ product division, adds, “Quite simply, this construction delivers the best aerodynamic performance and the best stiffness to weight ratio, bar none. [The Silverton SL and Capital SL] were developed as a complete and unique system with a fully optimised structure, meaning the spokes are optimised to work perfectly with the rim and hubs.

“The unique construction allows a uniform spoke tension, tuned from the spoke prestaining patented construction, ensuring the best performance from the composite material. In addition, it is a design that has maximum reliability in the long term, as there are no components that can fail or loosen over time.”

A ubiquitous alternative? Not for now

Given carbon fibre spokes have been around for more than 30 years and are still eye-wateringly expensive compared to their steel alternatives, the chances of prices falling and accessibility increasing might seem slim.

But a carbon-spoked future might be edging closer for those with moderately deep pockets.

“I think there will be more suppliers in the future for the ‘classic’ [unbonded] carbon spokes, and so the price in these segments will be falling,” says Hübner.

“I do see that carbon spokes are going to become ubiquitous,” agrees Smith, before conceding that because of the patents surrounding the tech, price falls will be modest.

“There are only one or two companies that are going to be able to produce them, because there’s so much intellectual property on the carbon spokes. This is going to be bad because I don’t think we’re going to be able to drive down pricing [because of it].”

However, for bonded wheels like Lightweight, expect price points to remain prohibitively expensive.

“Our engineering and production is based in Friedrichshafen, Germany. There’s no way to make it cheaper if you decide to produce it in Germany, and that’s obviously the reason why we have such a high price point,” concludes Lightweight’s marketing manager, Marco Hinzer.

“There are people out there who appreciate that we’re not going to China for production, so they’re willing to pay the price for it.”

In the immediate future, carbon fibre spokes are likely to remain the preserve of premium, range-topping, performance-focused wheelsets.

If prices do come down, or the aerodynamic and side-impact properties of unbonded spokes are improved to match steel, then they may become a viable and practical alternative for those seeking moderate weight savings without sacrificing durability.

Until then, carbon fibre spokes are likely to remain a niche product, albeit one where consumers with big enough bank balances have a greater choice than ever before.

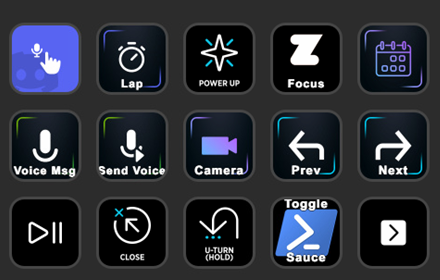

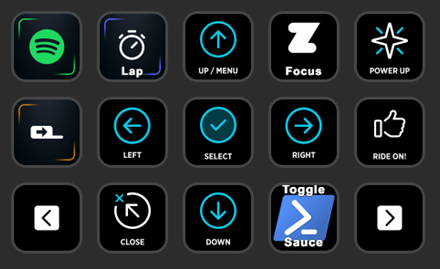

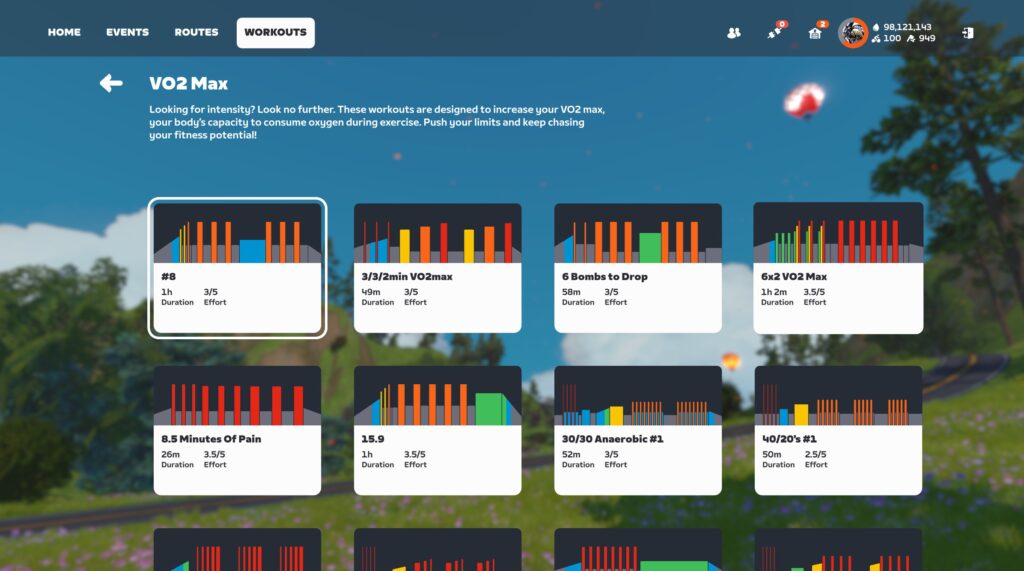

CTT Winter Series on Zwift

CTT Winter Series on Zwift

Popular

Popular  Giant Bagel Rolls Ride – Whitney’s Comeback

Giant Bagel Rolls Ride – Whitney’s Comeback